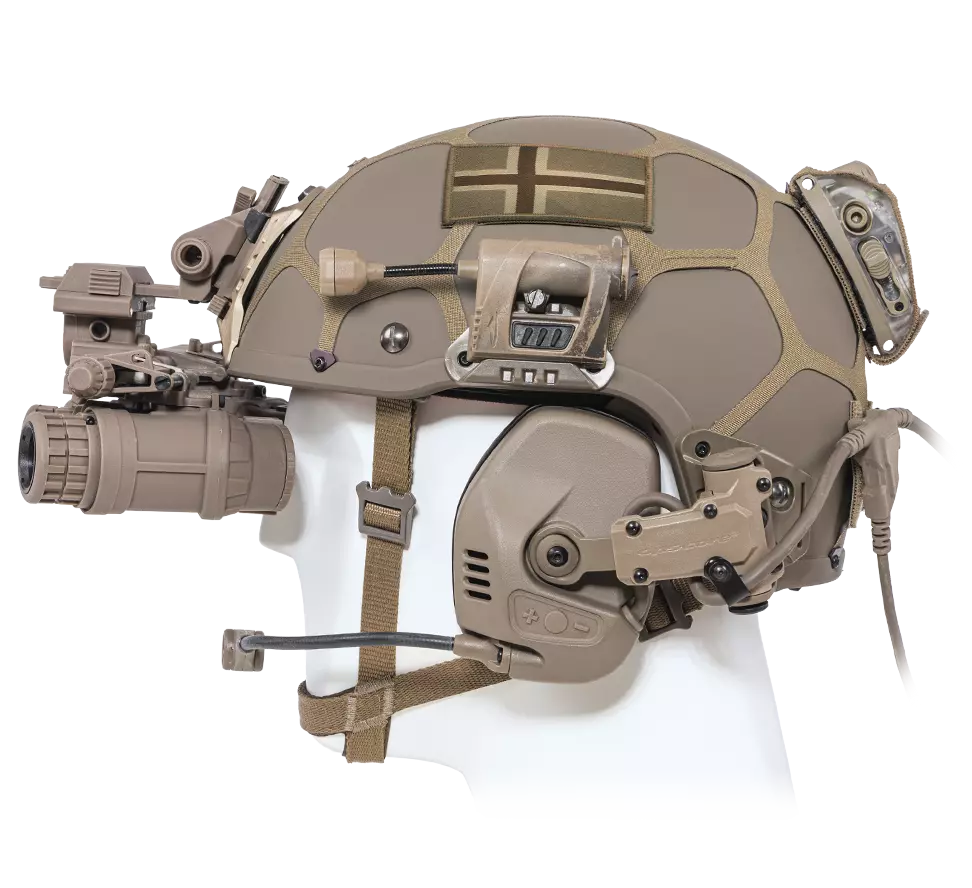

HJELM™ NFM Combat Helmet defines a new paradigm for equipment modularity and electronics integration without the extra weight and bulk of legacy systems. Improved capabilities for mission optimization and situational awareness are complimented by a ballistic shell and liner working to provide the highest level of protection and comfort available today.

HJELM™ Helmet System

NFM offers a complete combat helmet system, consisting of three helmets to accommodate every mission and end-user. All of our combat helmets offers unparalleled protection and comfort, and are designed to meet various threats.

LEARN MORE ABOUT OUR COMBAT HELMETS

HC 160F

The HJELM™ HC 160 F has been developed to meet the most demanding weight saving requirements while providing a high level of fragment protection.

HC 120MT

The NFM HC 120 MT is designed to counter a more extensive range of threats with an emphasis on maintaining a lightweight profile for operational agility.

TRIVIUM

The Trivium Ballistic combat helmet has been developed to meet the standards for the highest level of protection, without compromising comfort and agility.

FROM GJERMUNDBU TO HJELM™

Despite their spectacle-shaped face protection, designed to frighten and intimidate the opponent, and the spike on the crest, rendering a head-butt potentially lethal, the Gjermundbu helmet provided limited protection and considerably less comfort than helmets available today. Nonetheless, our Viking ancestors prized their helmets or hjelm, which were carefully preserved, repaired as needed, and passed from generation to generation, sometimes being used for centuries until the iron became too thin and weak to provide any real protection.

GENERATION-I

In the summer of 1915, the large number of lethal head wounds that artillery inflicted upon the French Army led them to introduce the first modern steel helmets, closely followed by the first British combat helmet to be specifically designed and engineered for Western Front battlefield conditions. These helmets were in reality no different in construction than the metal helmets worn by Roman soldiers in ancient times and are considered the first generation of military helmet design.

GENERATION-II

Generation II was marked by the invention and adoption of Kevlar material bringing about improvement in both protection and weight. The composite material construction of aramid fiber and resin for the ballistic shell was very good at stopping high speed fragments as well as most caliber handgun bullets.

GENERATION-III

Wearing technology on the head for purposes other than protection started the third generation of military helmet evolution. In the early 21st century, use of communication headsets and night vision goggles became common place and required a new level of helmet integration with accessory components. The earliest versions of these third generation helmets incorporated night vision mounts and ballistic shells trimmed higher to provide clearance for headset earcups.

HJELM™ – A GENERATION-IV HELMET

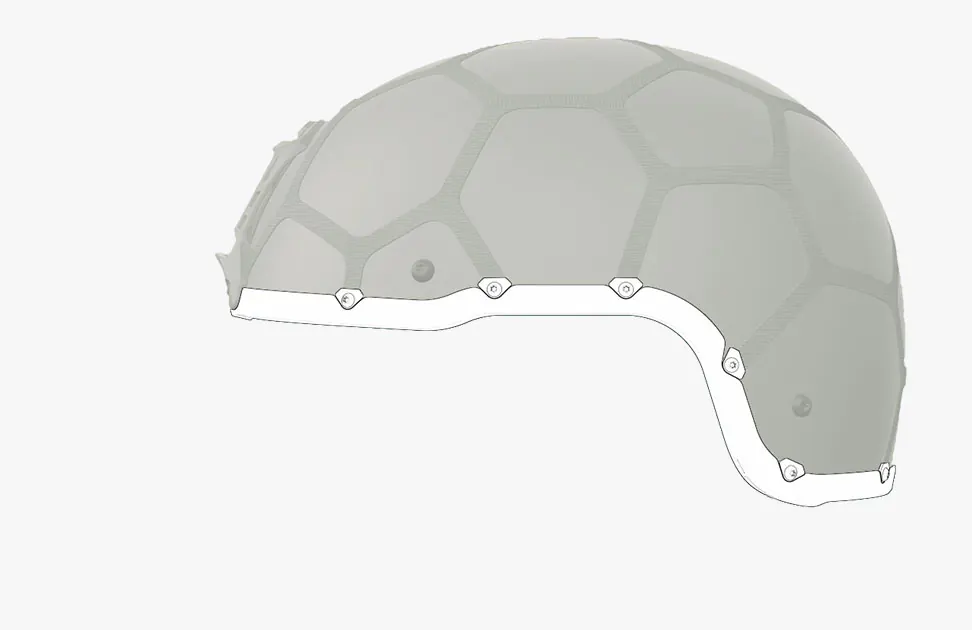

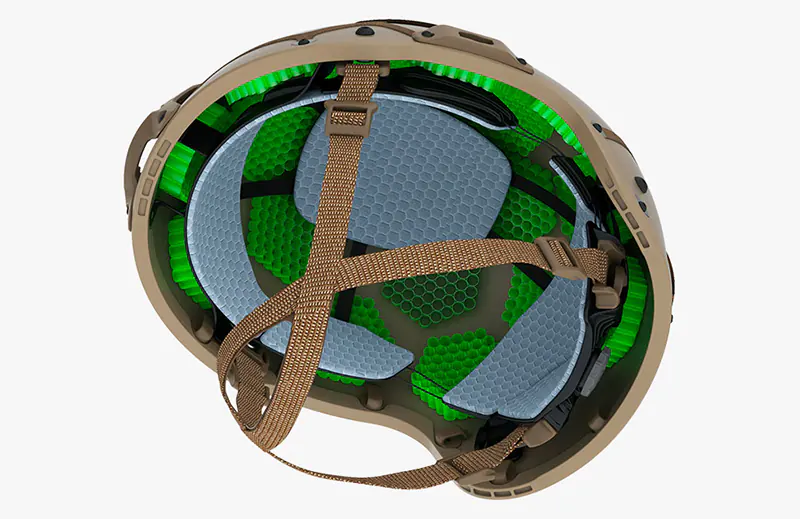

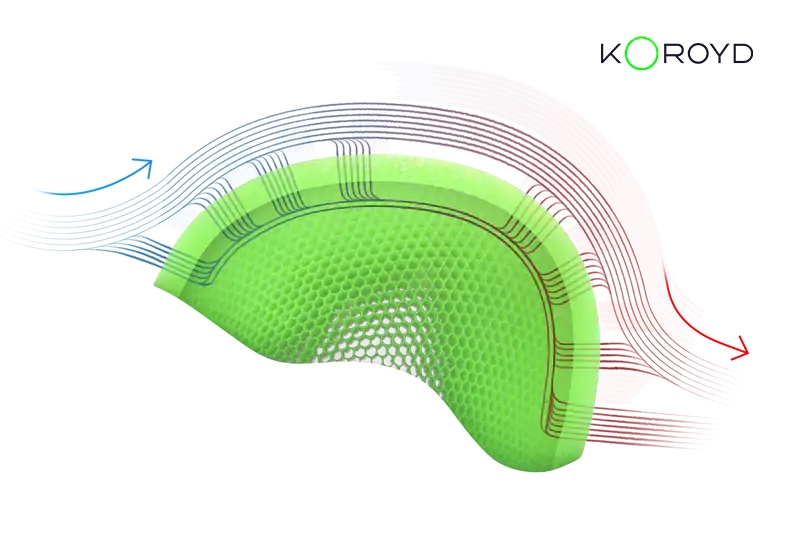

The NFM HJELM™ helmet line was developed to be the first Generation-IV ground infantry platform capable of integrating information technology while advancing protection from battlefield threats. The foundation for this system is an internal liner system that holds the helmet on the head comfortably and securely. It is coupled to a lightweight shell made from the highest grade of ballistic materials, and every gram of performance is optimized with state-of-the art processing techniques.

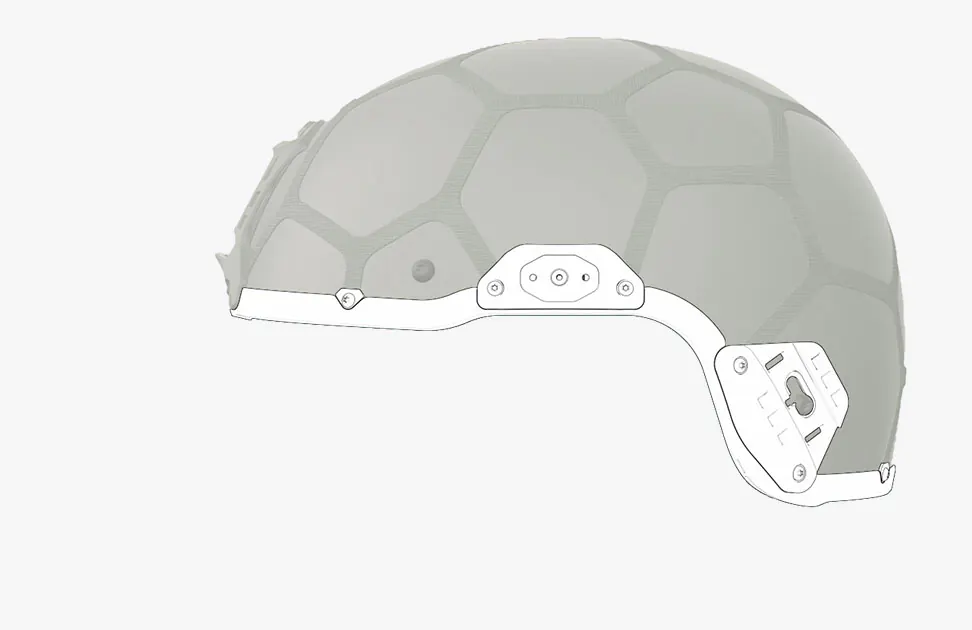

What makes HJELM™ a truly Generation-IV helmet is the Edgemount™ with Helmet Attachment System Pattern (HASP™). Unlike traditional rails and Velcro® which have limited attachment options and added material to the outside of the helmet, independent of devices being attached or not, the Edgemount with HASP means technology can be integrated only where it is needed.

JOIN OUR NEWSLETTER

Do you want to know more about HJELM™ Helmet system?

Send us a message via form below.