No weight without purpose

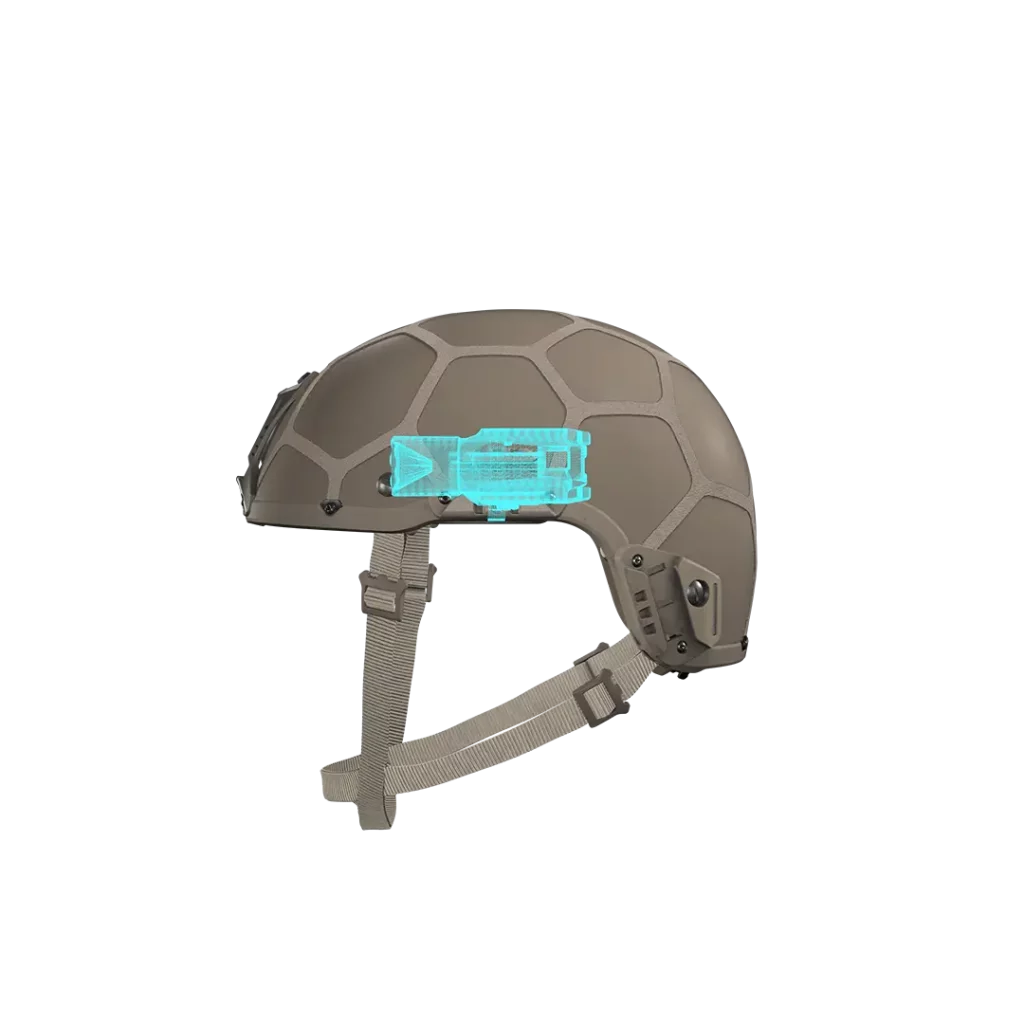

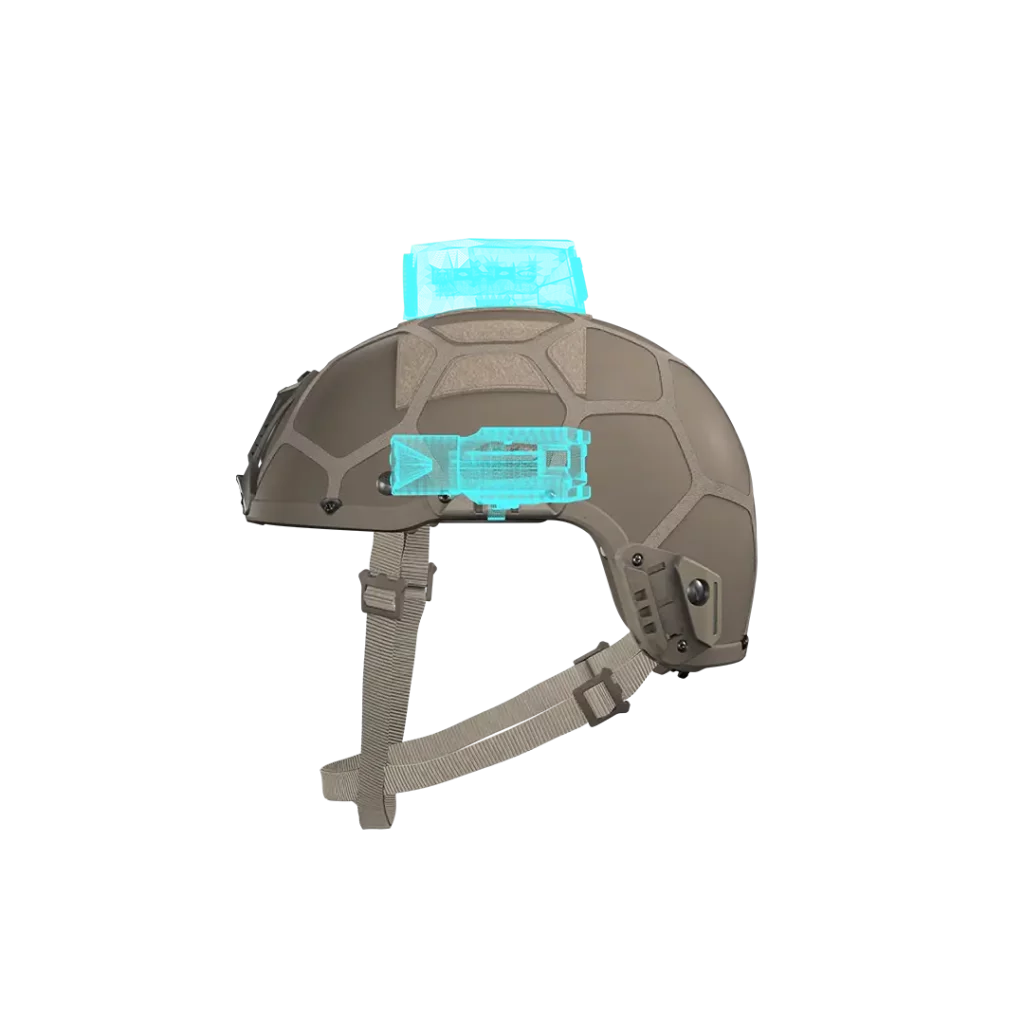

The motivation behind HJELM™ was to make to the lightest combat helmet possible, by only adding weight when it serves a function. Driven by this idea and technology, the Edgemount™ Attachment System provides the flexibility to attach only the accessory equipment that is desired.

The Edgemount™ is placed at the helmet’s edge and features lightweight hardware mounting points along the edge band of the helmet, an area where the helmet doesn’t provide ballistic protection. The Edgemount’s mounting points can be used to attach the NFM HASP™ (Helmet Attachment System Pattern) cover, a robust and elastic cover that spans the entire surface of the shell.

Innovative Approach Shreds Weight

Most combat helmets use a rail system for attaching accessory equipment to the helmet. However, rails are heavier and often require more space and material than necessary.

“The rails equal 10 percent of the weight of a light combat helmet, to make this attachment optional for the helmet was an important move to shred some weight. “, explains Thomas Hvesser, Director of Strategic Projects at NFM and one of the key contributors behind HJELM™.

Lighter load, enhanced freedom

NFM’s patented Edgemount™ Attachment System provides the flexibility to attach only the accessory equipment that is desired. If a soldier only requires a torch for a mission, this is all the mounting hardware that is attached, and the soldier will not be heavied down with unnecessary weight.

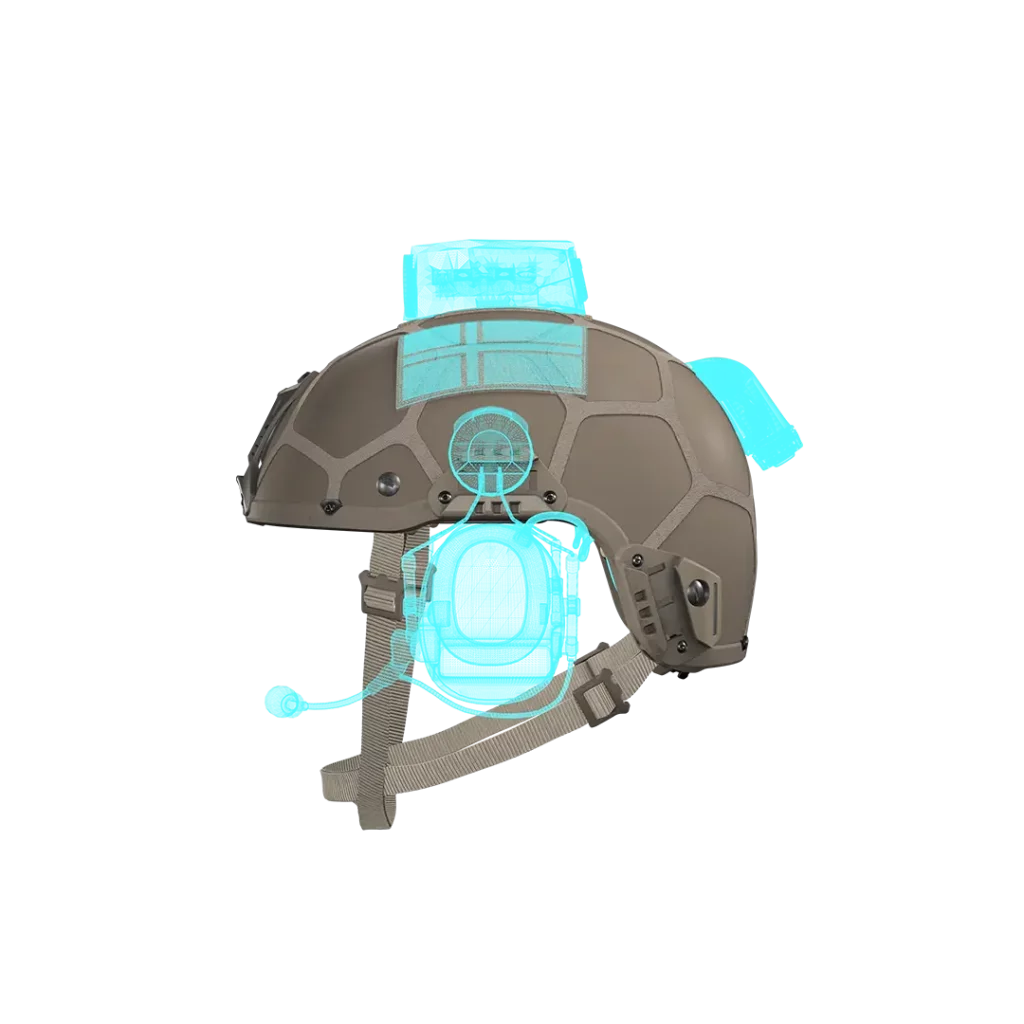

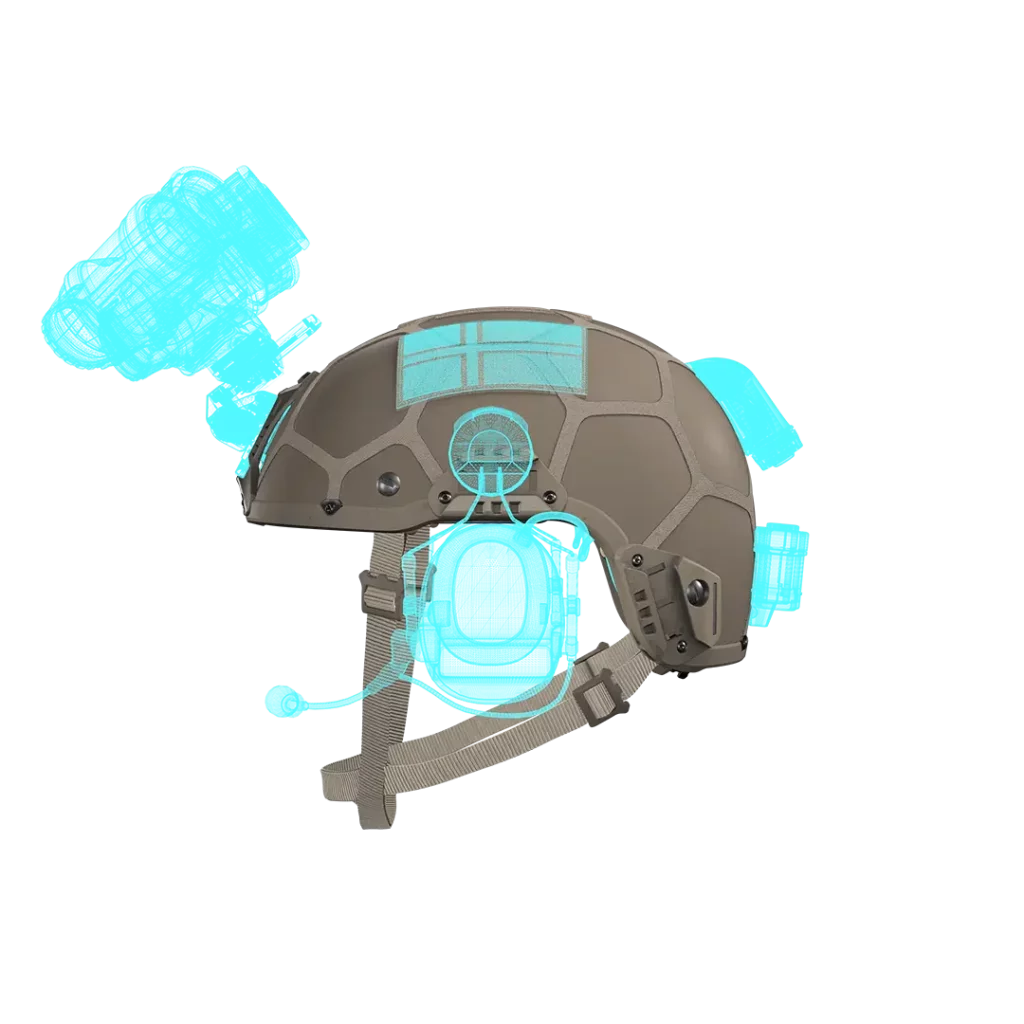

Our helmet system is compatible with most of accessories available on the market, ensuring seamless integration with various communication systems and horizontal accessory attachment options such as Peltor™, ComTac™rail mounts.

Additionally rear attachments like Ops-Core ARC™ and Ops-Core AMP™, further expand its adaptability to meet the diverse needs of users in different operational environments. The advanced liner system is designed to work effectively with stand-alone headsets that don’t require attachment to the helmet, providing flexibility and comfort in and comfort in communication equipment choices.

Sophisticated cable management

The Edgemount™ has an intelligent cable management system, allowing integration of wiring and connectors inside the helmet to enhance the HJELM™ combat helmet’s sensory technologies. This provides soldiers and technology manufacturers with the flexibility to arrange these devices for optimal function while safeguarding cables and connectors from damage or external snag risks.

The flexibility of the Edgemount™ System optimizes mission configuration.

Optimizing mission configuration

The flexibility of the Edgemount™ System extends beyond weight reduction to optimizing mission configuration, offering a revolutionary approach to combat helmet technology.

The unique attachment system

The principle of not adding weight without function, led to the development of the NFM HASP™. The system enables technical devices and camouflage to easily be attached to the helmet, without adding unnecessary weight.

For most combat helmets on the market, Velcro® has been used as an attachment system to fasten devices like ID patches, IFF devices, and cameras. But the strength of this material degrades over time, which may result in an unreliable connection to the helmet.

Replaces the Velcro®

The 360° HASP™ Helmet Attachment System Pattern replaces the Velcro loop with a high strength composite that provides a stronger and more reliable system throughout the shell exterior. Devices can now be mechanically attached without fear of the connection failing.

Signature Management

Small equipment-specific bases with extra safety latches can be used to secure heavier equipment, and simple, flat Velcro bases for patches (unit ID patches, etc.). The HASP™ is removable so that it could be replaced even in the field if it does become damaged.

Camouflage

Different types of camouflage can easily be attached and adapted to the HASP™ system, including natural material like leaves, knots and grass, or textile versions like the NFM Troll Hair™ or helmet covers. The HJELM™ surface is receptive to NFM’s EC paint™, providing greater customization options to suit any environment.

The HASP™ represents a highly adaptable and robust system designed to provide the utmost flexibility in combat helmet applications. This innovative solution is crafted with a focus on the end-user, ensuring versatility and durability for optimal performance in all operational scenarios.