HJELM™ HC120MT

DESCRIPTION

The HJELM™ HC120MT provides a comprehensive spectrum of protection, encompassing enhanced bullet and fragment resistance. ‘MT’ denotes ‘Multi-Threat,’ and this helmet ffers a more budget-friendly alternative, targeting conventional military forces and specific police units.

KEY FEATURES

- Best Weight-Performance-Ratio in the market featuring FREC-2™ pressing technology

- Unique Sizing System

- New Interior Design Concept:

- Skullplate Liner System

- Chinstrap variants

- Impact Management by KOROYD

- Superior Comfort, Load Distribution, Stabilization, Ventilation

- Modular Open Interface Architecture:

- EDGEMOUNT™ ADAPTER SYSTEM

- HASP™

- Lightweight Shroud

- ACH-SCA Rail (optional)

- Integration and Compatibility with a wide range of System Components and Accessories

- Ensuring Situational Awareness and Signature Management

- Adaptive Operational Capabilities

AVAILABLE COLORS

Raptor Green

NFM MTC

Coyote Brown

Raven Black

Hellhound Grey

PRODUCT FEATURES

The shell

With our unique technology we have made the lightest ballistic shell available, without compromising on the protection level.

The heaviest component in a ballistic helmet is the shell. NFM has developed a patented revolutionary processing FREC-2™ technology to take this capability one step further and bring the very lightest ballistic manufacturing to the HJELM™ product line, providing the opportunity for unprecedented weight savings while retaining protection levels.

The shells have a superior sizing system and are available in several colors and finishes.

Shape and Sizing

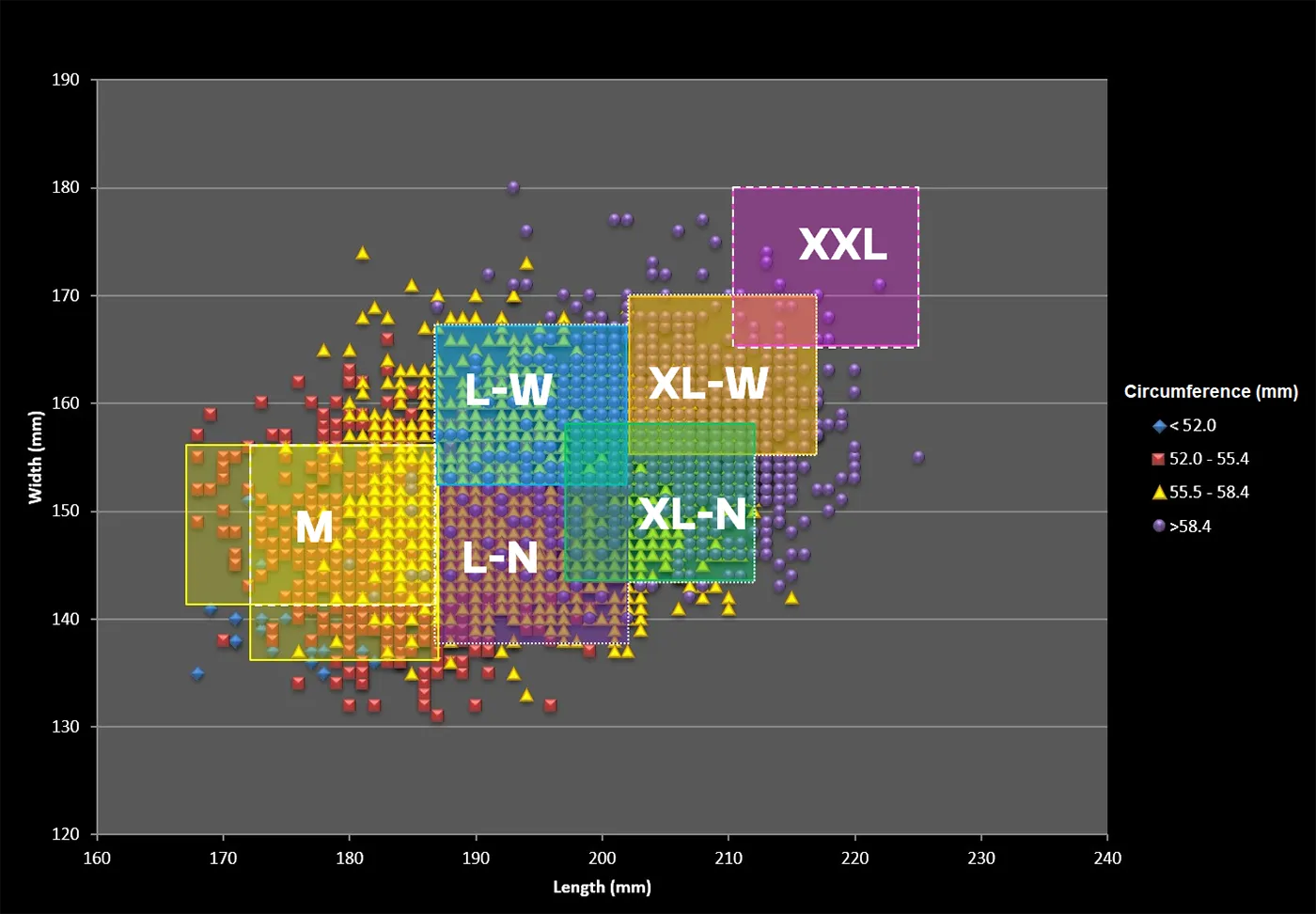

With our FREC-2™ technology, research and testing we manufacture the only ballistic helmet on the market today that comes in such a wide individually customizable range.

NFM has developed six different ballistic shell shapes for our HJELM™ product line, offering four main sizes in two different widths variants. Every user will be able to wear a helmet that more closely matches the size and shape of her/his head. The result of a close match and lower shell weight is an end user with the very best solution for improved comfort and reduced target acquisition times. Which means that the operator is not carrying around unnecessary weight.

Our sizing is based on the actual lengths and widths of several thousand 3D-scanned heads, from which the splits between the helmet sizes were chosen.

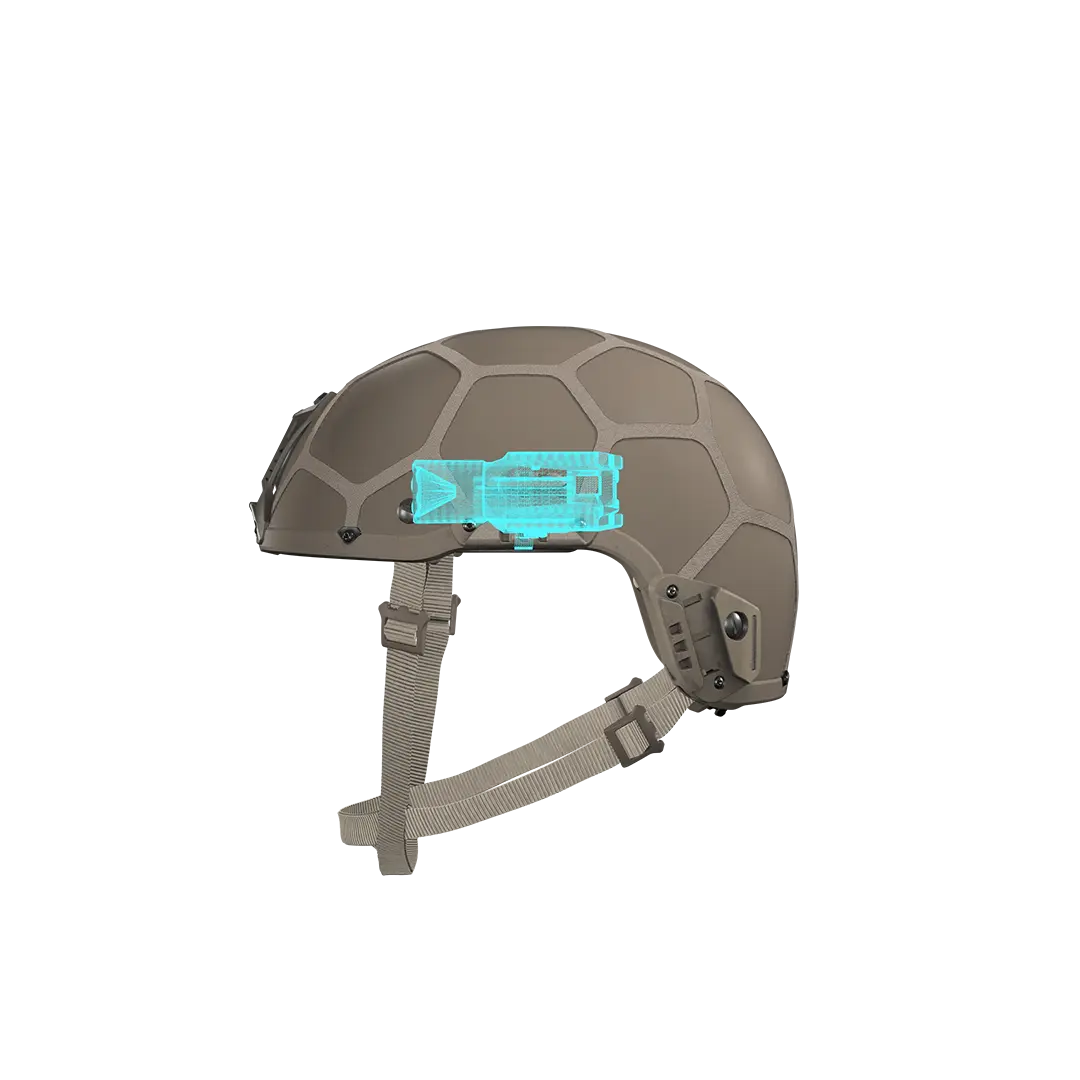

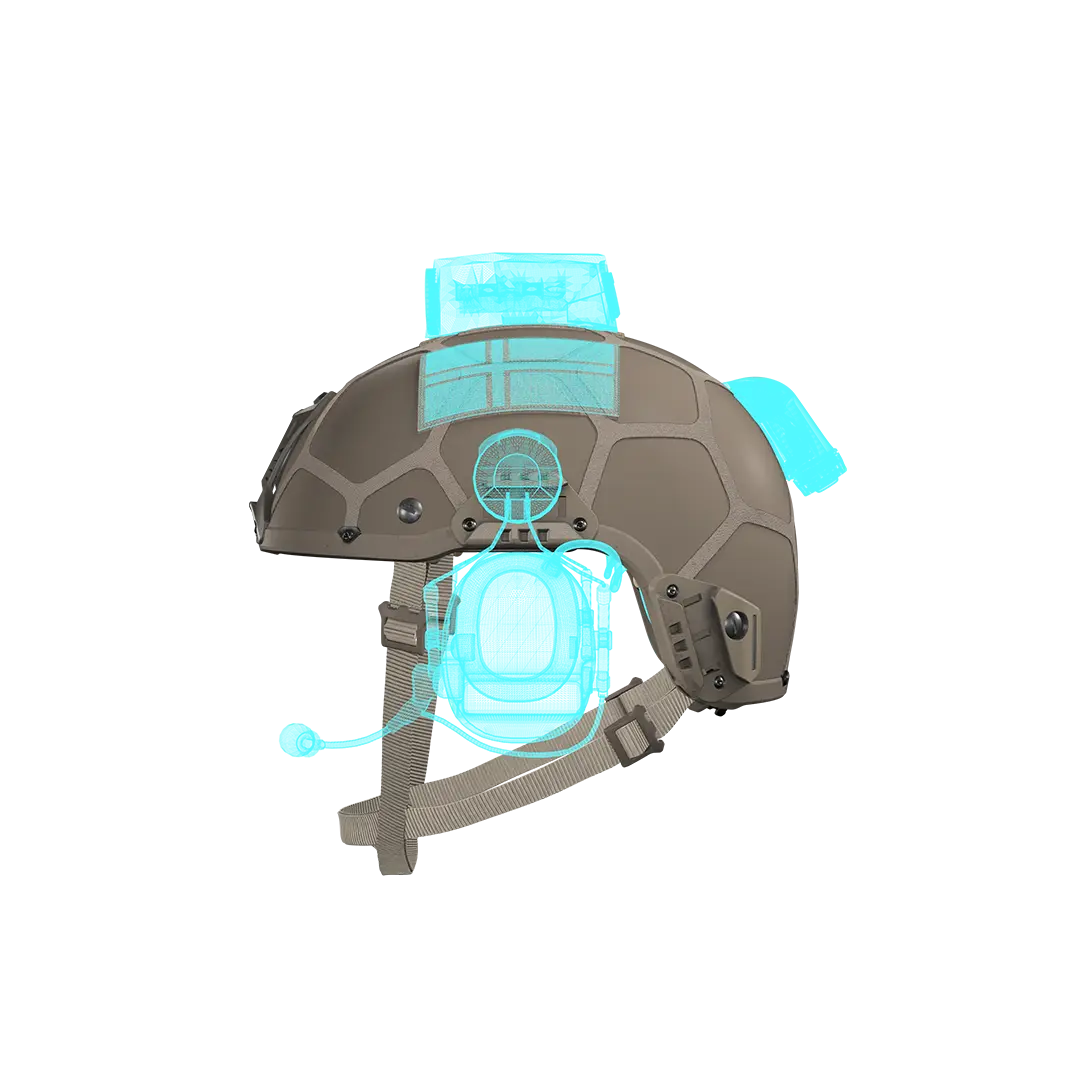

EDGEMOUNT™

Driven by technology the Edgemount™ Attachment System provides the flexibility to attach only the accessory equipment that is desired, with no added weight without function.

Most combat helmets use a rail system for attaching accessory equipment to the helmet.

However, rails are heavier and require more space and material than is necessary. The fundamental idea behind creating HJELM™ was to make the lightest combat helmet possible, by only adding weight when it has function.

That is why NFM’s patented Edgemount™ Attachment System provides the flexibility to attach only the accessory equipment that is desired. If a soldier only requires a torch for a mission, this is all the mounting hardware that is attached, and the soldier will not be heavied down with unnecessary weight.

The Edgemount™ has an intelligent cable management system, allowing integration of wiring and connectors inside the helmet to enhance the HJELM™ combat helmet’s sensory technologies. This provides soldiers and technology manufacturers with the flexibility to arrange these devices for optimal function while safeguarding cables and connectors from damage or external snag risks.

The flexibility of the Edgemount™ System optimizes mission configuration.

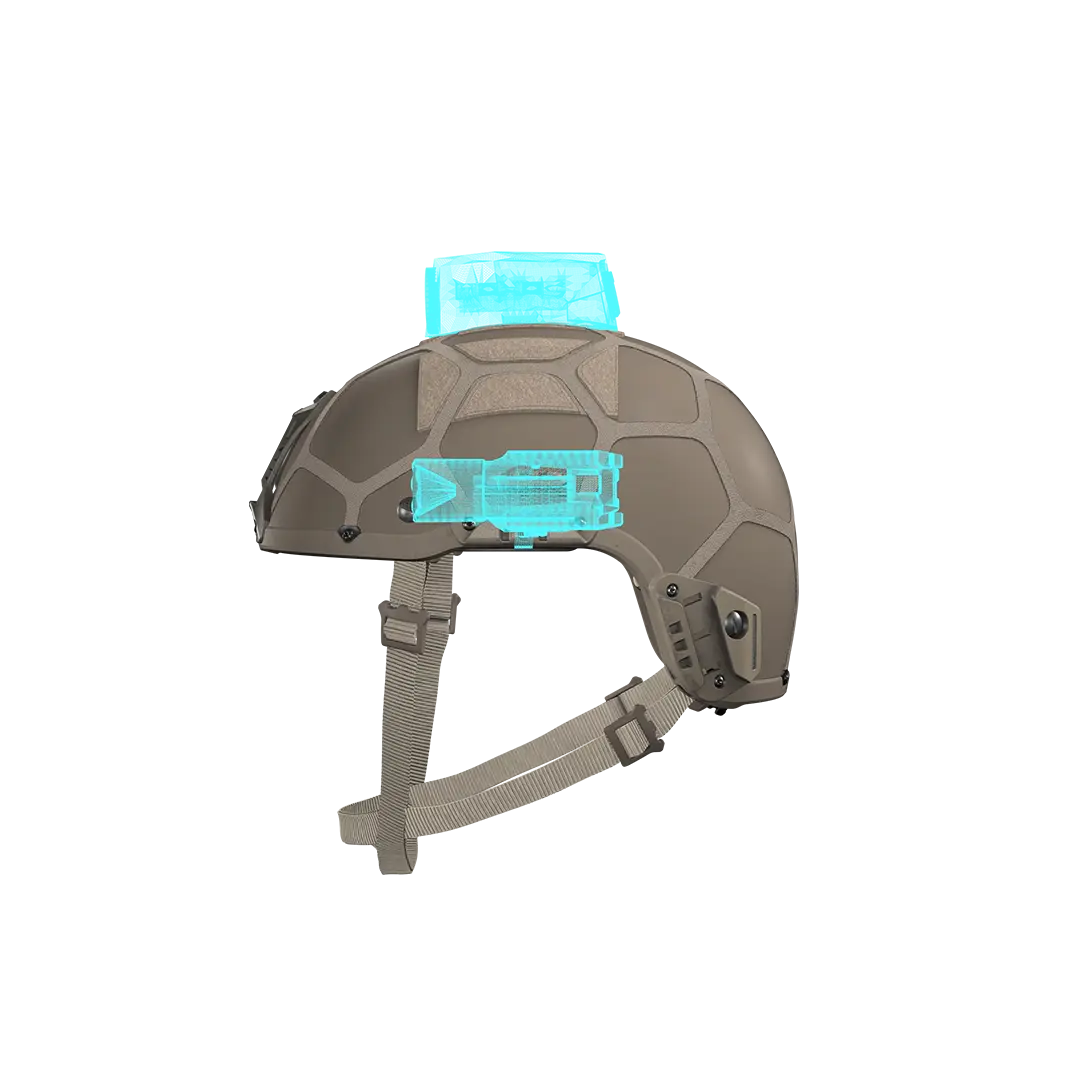

HASP™ (Helmet Attachment) System Pattern

For most combat helmets on the market, Velcro has been used as an attachment system to fasten devices like ID patches, IFF devices, and cameras. But the strength of this material degrades over time, which may result in an unreliable connection to the helmet.

The 360° HASP™ Helmet Attachment System Pattern replaces the Velcro loop with a high strength composite that provides a stronger and more reliable system throughout the shell exterior. Devices can now be mechanically attached without fear of the connection failing.

Small equipment-specific bases with extra safety latches can be used to secure heavier equipment, and simple, flat Velcro bases for patches (unit ID patches, etc.). The HASP™ is removable so that it could be replaced even in the field if it does become damaged.

Different types of camouflage can easily be attached and adapted to the HASP™ system, including natural material like leaves, knots and grass, or textile versions like the NFM Troll Hair™ or helmet covers. The HJELM™ surface is receptive to NFM’s EC paint™, providing greater customization options to suit any environment.

NEW FUNCTIONAL DESIGN

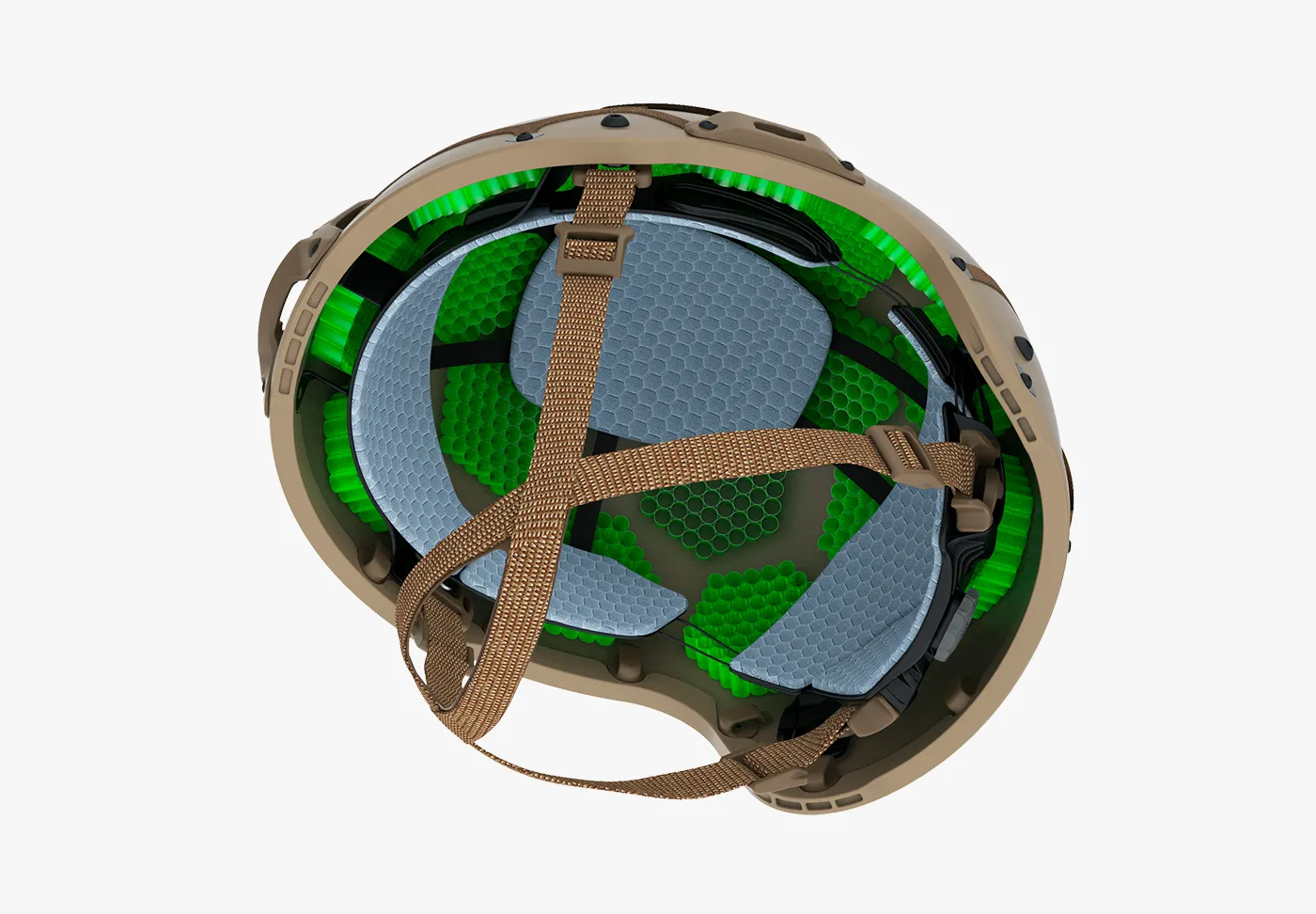

HJELM™ Skullplate Liner System

HJELM’s Skullplate Liner System solves the problem of comfort and stability with new advancements in technology, providing a lightweight design which is capable of changing shape and size to match the user’s head while providing optimal helmet stability.

The Skullplate Liner System can be adjusted in length, widths, height, and circumference, ensuring a personalized and comfortable fit for each user without compromising protection. Even the angle of the Liner System to the shell can be positioned. The system can be adjusted by Wheeldial Technology all around the head. It excels at safeguarding against rotational impacts, a key concussion factor.

Despite advanced features, it remains lightweight for extended wear. Because we created a gap between the Skullplate Liner and the shell, the system enhances ventilation and moisture management, reducing the buildup of moisture inside the helmet. Quick one-handed adjustments add to the enhancing of mobility and durability. Replaceable, washable comfort pads further enhance the system’s versatility.

The Skullplate liner system contributes to the right weight distribution, ensuring top performance in comfort and impact protection.

HJELM™ Chin strap

In addition to traditional chinstrap options, HJELM™ offers a revolutionary new chinstrap which can remove the buckle from the chin. Not only is this more comfortable, but it does not interfere with CBRNE Oxygene masks or when sighting weapons, regardless of eye dominance.

HJELM™ combat helmets offer a variety of different Chin straps, all designed for quick releases with no need for tools. The range of chin strap options, including those with or without chin-buckles and designed for both right- and left-handed users, provides soldiers with the flexibility to choose the version that best suits their mission. A chin strap adjusted to the soldier and the mission provides a stable and comfortable fit to the helmet. It ensures proper weight distribution and prevents the helmet from slipping on the head when attaching additional devices.

The combination of Skullplate Liner System and Chinstrap delivers an unrivaled stabilization and load distribution of the helmet in his function as a sensor platform.

THE ULTIMATE DAMAGE CONTROL SYSTEM

Advanced impact technology

Koroyd provides advanced breathability and ultralight feel, but first and foremost, better protection which may reduce the risk of suffering a life-affecting injury.

Koroyd ultimate protection works better because it uses core tubular technology, absorbing most energy by creating crumple zones. Koroyd’s welded tubes crumple instantly and consistently on impact, absorbing maximum force in a controlled manner, minimizing energy transferred to the head. This outperforms other materials at every stage of compression, helping reduce the risk of injury, making it the ultimate damage control system and the optimal material for combat helmets.

Impact protection

Studies show that in the event of an angled impact, when direct acceleration is reduced by absorbing energy, there is a 91% correlation with a reduction in the rotational motion of your head and brain. In simple terms, if your helmet absorbs more energy, you are better protected from any angle of impact.

Breath & Flow

The protective core covers strategic zones whilst the open cells allow hot air to escape and fresh air to go with your flow.

Ultralight

Koroyd is 95% air. This enables lighter, smaller, faster protection, causing less fatigue for life on the move.

Operational Compatibilites

HJELM™ is compatible with most helmet-born communications headsets available on the market today. A rear accessory attachment is available for the perfect integration with rail mounted headset, mounted both above or behind the ear. The HJELM™ liner system also works well with several stand-alone headsets that do not attach to the helmet at all.